The advantages of stamping technology

In foam technology, there are two common methods for cutting foam: die-cutting and kiss-cutting.

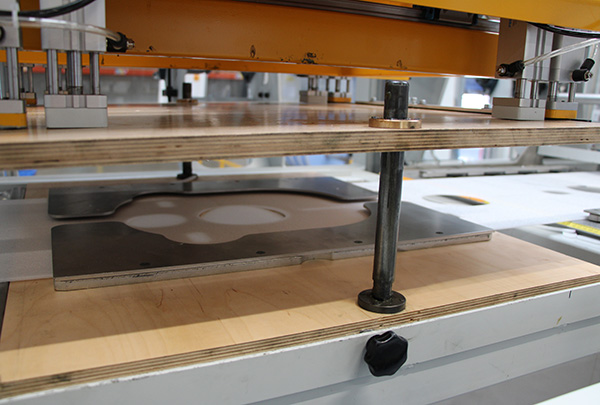

In die-cutting, a special die-cutting tool is used to cut foam into a specific shape. The punching tool consists of a sharp blade embedded in a rigid plate. During the die-cutting process, the tool pushes through the cellular plastic to cut the foam. Die-cutting is well suited to the production of large formats of foam parts with a specific shape, and the automated process is fast and efficient.

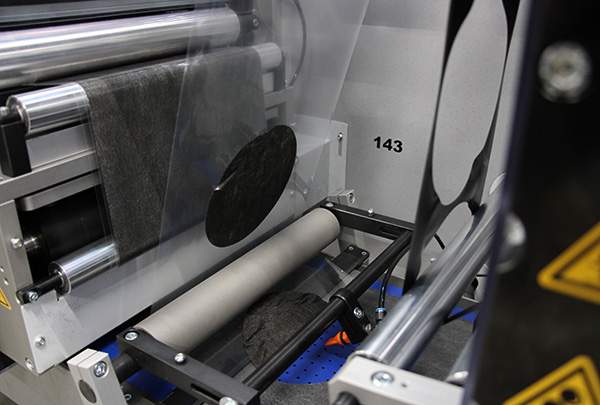

In kiss-cut and rotary die-cutting, the self-adhesive foam is also cut with a die-cutting tool, but only the foam and adhesive are cut without cutting through the siliconized cover film or paper. The kiss-cut process (stroke) and the rotary die-cutting technique make it possible for the self-adhesive foam to be easily removed from the backing film and applied to another surface.

![[Translate to Englisch:] Sanitärkeramikstreifen](/fileadmin/_processed_/0/0/csm_DD_hySilent-Vergleich-2_94f300c2d2.jpg)